From Condition Found Reports (CFRs) to Test/Inspection Plans (TIPs) and everything in between.

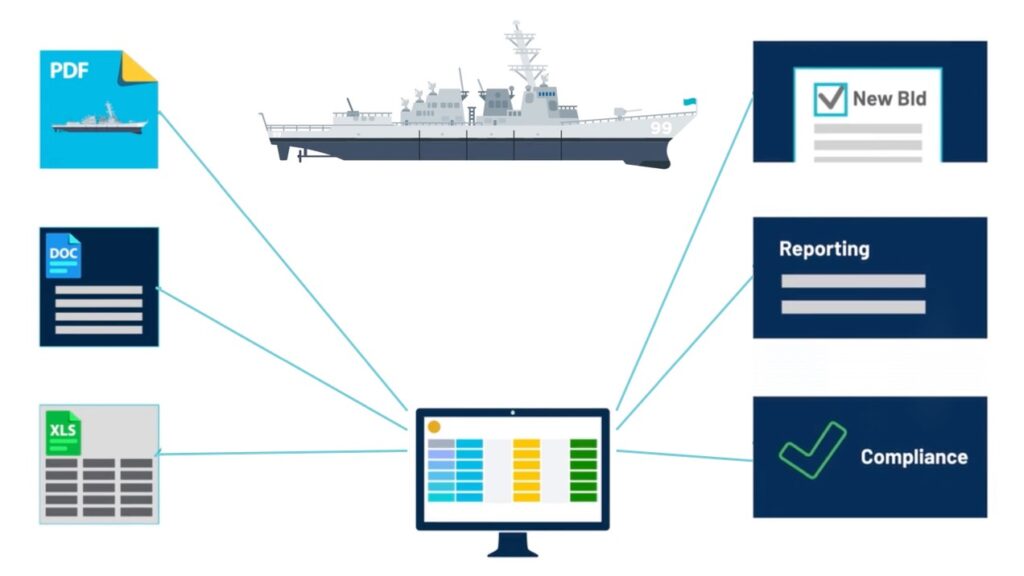

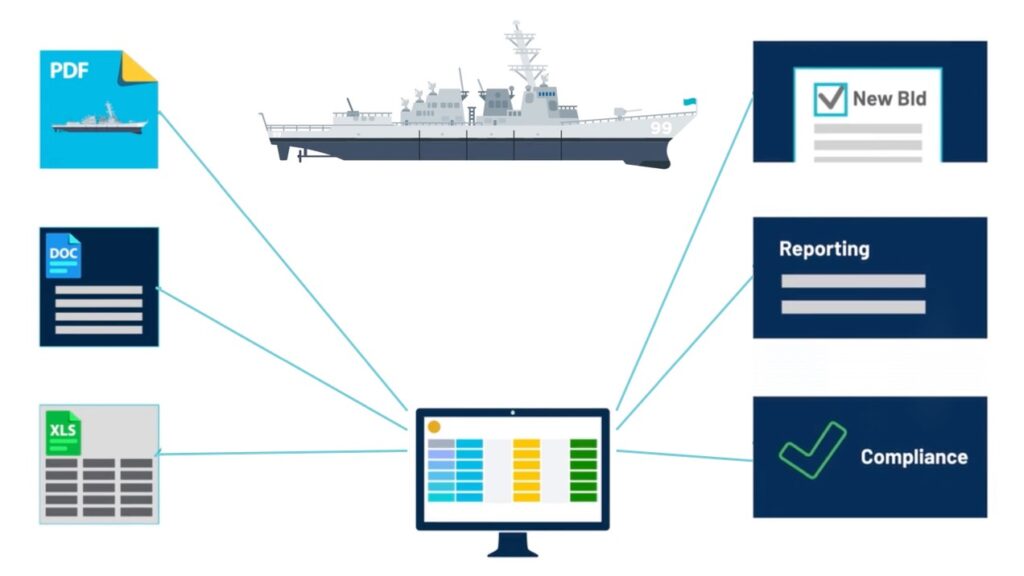

Oxalis Ship Repair System (OSRS) is purpose-built for shipyards servicing U.S. Navy and Military Sealift Command (MSC) contracts. Designed in partnership with maritime leaders, OSRS replaces spreadsheets, manual workflows, and siloed systems with a centralized platform that streamlines operations.

Whether you’re digitizing operations, enhancing compliance, or reducing turnaround times, OSRS gives you the structure, security, and insight to get the job done right.

Why Oxalis Ship Repair System?

Modern Ship Repair Demands Modern Tools

Shipyards are under pressure to deliver more—faster, more securely, and in full alignment with Navy and government expectations. OSRS was purpose-built to help you:

Streamline CFRs and TIP workflows

Automate compliance documentation and reporting

Replace paper forms with secure, customizable digital workflows

Collaborate with subcontractors and customers—safely and efficiently

Ensure NIST 800-171 and DFARS 7012 compliance

What Oxalis Ship Repair System Delivers

Structured, Scalable Workflows

Ditch the spreadsheets. OSRS provides a single source of truth for your repair projects—with form-driven task flows, approval checkpoints, and real-time visibility from estimate to closeout.

Secure Collaboration—Built In

Whether you’re working with internal teams, subcontractors, or government agencies, OSRS keeps communication controlled, compliant, and efficient.

Compliance Without Compromise

OSRS meets or exceeds the requirements of high-security environments:

OSRS in Action

Key Capabilities That Power Shipyard Success

SLA Management

CFRs

Government Reporting

Test & Inspection Plans

Subcontractor Portal

OSRS vs. the Status Quo

| Feature | OSRS | Legacy Tools |

|---|---|---|

| CFR & TIP Management | Integrated | Manual / Fragmented |

| Subcontractor Portal | Secure Access | Email-Driven |

| Government Reporting | Automated | Time-Intensive |

| Security Compliance | DFARS / NIST / ITAR | Risk-Prone |

| SLA Monitoring | Real-Time Alerts | No Visibility |

Built for the Future: AI-Ready Shipyard Operations

Smart Integrations. Faster Decisions. Greater Impact.

OSRS is designed not only to streamline today’s operations—

but to support tomorrow’s innovation.

With optional AI connectors, OSRS enables intelligent agents to analyze CFR and TIP data, identify patterns, surface insights, and even trigger next actions automatically.

AI-enhanced capabilities include:

- Automated routing and recommendations based on issue type or severity

- Predictive CFR analysis to flag trends or recurring issues

- Decision support for project managers reviewing repair performance

- Anomaly detection for QA and compliance

These AI connectors give shipyards an edge in efficiency, accountability, and decision-making—especially in complex MRO environments where precision and speed are mission-critical.

Looking to future-proof your operations?

A System That Evolves With You

Your Shipyard. Your Rules. Our Support.

When you choose OSRS, you’re not just implementing software—you’re gaining a long-term partner.

Our team continuously refines the platform based on customer feedback and evolving government requirements.

- Dedicated onboarding and project support

- Regular feature updates and roadmap reviews

- Flexible implementation to match your environment and pace

Ready to Transform Your Shipyard?

See why leading shipyards trust Oxalis to modernize their repair operations and meet the toughest compliance requirements.

Oxalis Ship Repair System (OSRS) is a secure, purpose-built platform for Navy and commercial shipyards. It centralizes ship repair operations—including CFRs, TIPs, and subcontractor collaboration—into a single, compliant system that replaces manual processes with secure digital workflows. With automated reporting, real-time visibility, and full alignment with DFARS, NIST 800-171, and ITAR, OSRS helps shipyards modernize operations, meet government requirements, and accelerate project delivery.

Contact us

FAQ’s

How does OSRS help Navy shipyards stay compliant with DoD and MSC regulations?

Oxalis Ship Repair System (OSRS) automates compliance by integrating with the Navy Maintenance Database and supporting NIST 800-171, DFARS 7012, and ITAR requirements. This centralized approach ensures all activities, documentation, and reporting across shipyard operations meet current Navy and MSC standards. Shipyards in regions like Norfolk and San Diego benefit from fewer manual compliance tasks, less risk of errors, and faster adaptation to regulatory changes.

How do shipyards manage limited dock space during busy periods?

Efficient management of dock space is critical during busy ship maintenance cycles, especially at high-traffic naval hubs. Oxalis OSRS tracks repair schedules and project progress in real time, helping managers optimize dock assignments, prioritize critical jobs, and minimize bottlenecks during high – demand periods. By visualizing upcoming projects and conflicts, shipyard leaders can efficiently allocate dock space to support mission-critical repairs and maximize throughput.

How can OSRS improve local shipyard operations?

Digital tools are transforming how Navy shipyards coordinate repairs, documentation, and compliance activities. With Oxalis’s OSRS, shipyards can digitize workflows, automate reporting, and centralize CFRs and TIPs—simplifying everything from subcontractor collaboration to compliance documentation, and improving turnaround times at facilities. See how OSRS streamlines shipyard scheduling and operations.

Which software tools best support coordination across regional MSC shipyard facilities?

Coordinating complex repair operations across multiple shipyards requires a secure, centralized management platform. Only Oxalis OSRS delivers cloud-based repair management designed for MSC and Navy networks. Shipyards across coastal regions can securely share updates, standardize reporting, and coordinate resources—all within a single platform built for distributed operations.